the challenge

To design an electric-driven high pressure pump package with integrated variable speed drive (VSD) for operation in ATEX Zone 1 & 2 hazardous areas.

For many years we have designed and manufactured both diesel and electric drive pump units for offshore fabric maintenance activities. Most of these pump packages are containerised. However, where a VSD was required in an ATEX hazardous area, the VSD drive had to be mounted in a separate container due to its size. For reasons of cost, the VSD container would be mounted in a safe area of the platform with cabling connecting the pump and VSD.

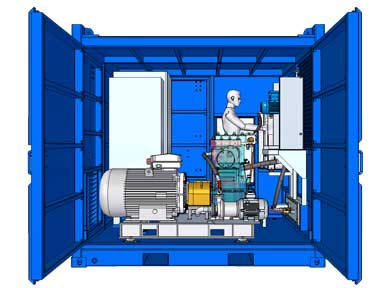

We identified the need to manufacture pump units with integrated hazardous area VSDs. This would give the operator a single, compact container to accommodate the pump, motor, VSD and all the ancillary equipment. An additional aim was to significantly reduce the price of the VSD pump package so it could compete with diesel-driven units.

the solution

- We decided to engineer an electric drive system for one of our most popular pump models, with power ratings of 200kW and 140kW. The process was made more challenging by the requirement to ensure the new design was as compact as our existing diesel unit footprint, enabling our customers to choose electric drive units without penalties of increased unit size or weight.

- Due to the VSD technology, we understood there are heat dissipation requirements to overcome and we developed a cooling circuit design to ensure stabilisation of drive and lube circuits to allow operation within the temperature allowances for ATEX.

- The electric motor is lighter in comparison with our diesel engine unit design. This has allowed us to redesign our skid using Finite Element Analysis (FEA). This design optimisation had three benefits. Firstly, it ensured only the required materials were used, eliminating unnecessary structural materials use during manufacture. Secondly, the redesigned and, therefore, lighter skid reduced the overall unit weight. Thirdly, the skid design optimisation created a cost saving which was important as we wanted to bring the unit price in line with diesel units.

- A full ignition hazard assessment/survey and component selection analysis was required to ensure that new VSD drive technologies would be ATEX compliant. We also devoted time to ensure the new design would be compliant with other relevant energy industry legislation and would enable us to apply the same design philosophy to future Calder applications.

the result

We now have a Zero CO2 emissions, high pressure, ATEX Zone 1 or 2-compliant offshore pump unit with an integrated VSD. Operationally, it is important that the equipment comfortably fits inside a single 10-ft container certified to ISO 10855-1. Commercially, we have achieved all of this to give a unit price comparable with our existing diesel-driven unit alternative.

Get in touch

We are here to help you reduce your carbon footprint. Please call us on +44 1905 751790 or email sales@calder.co.uk.

Alternatively, our Electric Waterjetting Pumps for Offshore Hazardous Areas web page offers a lot more information.