Modular, Triple-pump Skid Package Despatched

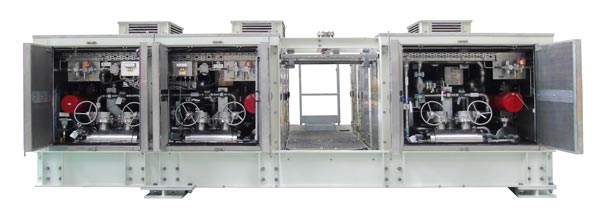

Product: Modular, triple-pump skid package

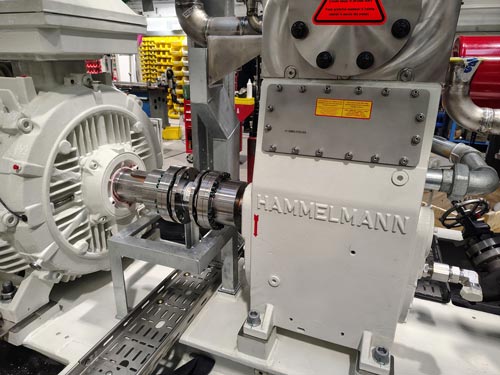

Pump: Hammelmann Hampro 140 series

Fluid: MEG (Mono Ethylene Glycol)

Hazardous Area Compliance: ATEX Zone 2 and NORSOK

Designed: Worcester, UK

Built: Worcester, UK

Tested: Worcester, UK

Testing is complete, the package has been disassembled, packed and despatched.

Requirement for a Modular Pump Skid

Our customer required a triple-pump skid for an existing platform in the Norwegian North Sea. The platform operational and both access and space are limited, thus presenting the type of design challenges on which we thrive. Over the last ten years or so, we have designed and manufactured an growing number of compact, modular pump skids. This is due in large part to the number of platform life extension projects and platform electrification projects.

This bespoke pump package, whilst in many ways typical of our

The Pump Package

The Pump and Pumped Fluid

The package features 3x electrically driven Hammelmann

Hampro 140 series pumps and will operate in a NORSOK hazardous area on a platform in offshore Norwegian waters. The pumped fluid is MEG (Mono Ethylene Glycol) with which we have huge experience. Check out our MEG pump package supply history.

Coupling Alignment – a crucial part of the build process.

The coupling between the pump and motor are quite standard for our chemical injection systems. Coupling manufacturers recommend maximum tolerances on alignment of rotating equipment. However, such is the importance we place on pump/motor alignment, we typically work to less than half the recommended tolerance. In order to achieve these greater levels of accuracy, we use the latest laser alignment equipment. This, coupled with the experience our build teams possess, ensures our stringent pump/motor alignment requirements are achieved.

Enclosure

The enclosure uses a steel framework with stainless steel doors. Acoustic panels line the doors internally and the doors provide full maintenance access.

Installation, Commissioning and Support

Our Life Cycle Services team will take over from this point. First, a team will be sent to the platform to assemble the pump skid modules in situ. Then will follow the system commissioning where our commissioning engineers will support the customers team. Mechanical installation checks, electrical and instrumentation checks, functional testing, and the final system wet run system commissioning.

As always, we will be here to support our customer with spares, service for the lifetime of the system.

Talk with us

Whatever your application, we are here to help. Offshore modular pump system? Hazardous area? High pressure? High flow?

Please call us on +44 1905 751790 or email sales@calder.co.uk to discuss how we can help you achieve your green future energy targets.