MANUFACTURER OF ENGINEERED

HIGH PRESSURE SOLUTIONS

Innovation Through Experience

HIGH PRESSURE SOLUTIONS

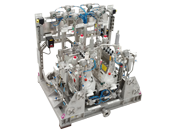

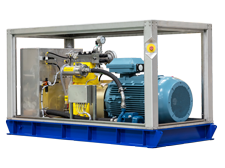

We design, assemble and test high pressure pump packages, vacuum systems, compressors, and many other flow solutions.

Our engineers specialise in packages for hazardous areas and we relish the challenges of packaged equipment weight and size reduction, and the pumped medium specified by our customers. Bespoke pump and unit designs make up much of our workload and our engineering knowledge and experience enables us to provide high pressure flow solutions for some of the most extreme operating environments on earth.

Standard pump products for both safe and hazardous areas are accompanied by a range of accessories. All are supported by our life cycle services team who provide spares, commissioning and service support worldwide.

Our success over four decades is founded on uncompromising quality and the incorporation of the very latest technologies into our products.

- Energy Transition – pump systems for geothermal, hydrogen, CO2, Power-to-X …

- Process – chemical injection, MEG injection, seawater injection …

- Well Service – CRI/waste injection, BOP test systems, well stimulation …

- Fabric Maintenance – paint removal, deck cleaning, decommissioning …

- Automotive – paint removal, conveyor cleaning, engine block de-burring …

- Nuclear – decontamination, decommissioning, auxiliary cooling …

- Petrochem – tank cleaning, tube bundle cleaning, surface preparation …

- Civil Engineering – formwork cleaning, white line removal, concrete removal …

- Ship Repair – surface preparation, abrasive cutting, pipe cleaning …

- Food & Beverage – conveyor cleaning, keg cleaning, vessel cleaning …

- Pharmaceutical – tank & vessel cleaning, tube & pipe cleaning …

Engineering design teams who thrive on a challenge

- Engineering design teams who thrive on a challenge

- 3D CAD software

- FEA Finite Element Analysis

- Blast Load Case

- Design Approach 2 Studies

From basic functionality to complete control system philosophy

- On-board control

- Remote operation

- System monitoring

- Fault finding

- Data acquisition and logging

- System performance/health monitoring

Two large, state-of-the-art, acoustically attenuated, test bays

- In-house VFD’s up to 1,800 kW

- 50 Hz and 60 Hz power supply

- Flow rates up to 250 m3/hr

- Pressures up to 4,000 bar

- Acoustic attenuation

- Exhaust extraction for diesel engine testing

- High ambient temperature testing up to 50°C

As bespoke engineering is a large part of our business, our case studies detail the work we do to find and deliver solutions for our customers.

A selection:

Product applications

Supporting Our Customers - Life Cycle Services

We are committed to providing comprehensive aftermarket support to ensure all our customers derive the optimum performance and value from their investment in Calder equipment. Product support is available 24 hours a day, 365 days a year. This is backed up by a team of experienced service engineers and technicians who are fully qualified and trained to support all aspects of Calder equipment, both onshore and offshore. They are supported by an extensive stock of spares and accessories. So whatever your equipment, high pressure pump packages, vacuum systems or offshore compressors, we are here to support you.

Featured Products

Latest News

ONS 2026 Stavanger, Norway

At ONS 2026 in Stavanger this August, we will be discussing our pump systems for...

ADIPEC 2025, Abu Dhabi

This year’s ADIPEC proved to be our busiest exhibition so far in our history.

a busy 3 months

It has been a busy 3 months here at Calder. Projects completed, exhibitions, pro...

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 1 year 1 month 4 days | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gat_gtag_UA_* | 1 minute | Google Analytics sets this cookie to store a unique user ID. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |