A Busy 3 Months Here at Calder.

Projects completed, exhibitions, projects in design, project build starts.

As we roll into autumn, a major project build has started in the factory and another will start before the end of October. However, the build commencement follows months of work from the detailed proposal stage, engineering reviews, bid clarification meetings, purchase order and then the engineering and design. We have been busy with exhibitions – always an important way to make new contacts and show our capabilities to a wider audience. The despatch of units that have been part of our everyday lives for many months through design, build and test gives us the opportunity to reflect on our achievemants, the technical challenges we have overcome, and perhaps the inevitable high and lows of every bespoke project.

Cooling Skid Despatched.

We were particularly pleased with this project. Not only was it technically challenging, but the finished pump skid looked fabulous. To see why we were so pleased with this package, click here to read the full article.

This cooling medium system, designed for ATEX Zone 1 hazardous areas, is part of a power-from-shore, platform electrification project.

Triple-pump Skid Package Despatched

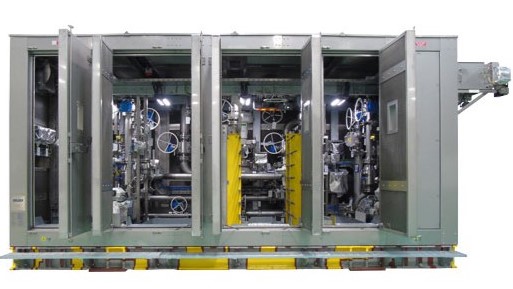

Following close behind the cooling skid was the despatch of a three-pump modular system for methanol injection. This pump package was truly impressive and will be commissioned on site by members of our service team. More about this modular pump system.

Compact and modular pump packages for offshore platforms have been a growing requirement over the last ten years or so. With platforms being re-purposed, or changing to electric power in power-from-shore-projects, new pumping systems are needed that can fit into existing deck space. An even greater challenge is sometimes designing pump systems that are modular to allow them to be moved into position in an already congested platform.

Exhibitions 2025

The Offshore Europe exhibition coupled with the Water Jetting Trade Show illustrate the breadth of the Calder range. We design and manufacture pump systems for high pressures and hazardous areas and serve a large variety of industrial sectors. So, you will see our units at the side of motorways undertaking hydrodemolition works, in refineries for tank and pipe cleaning, in shipyards for surface preparation, and on offshore platforms for process and well service applications. They can also be found on boats as net cleaning units and ships to inject green fuels for marine propulsion.

Offshore Europe 2025

We were pleasantly surprised at Offshore Europe. Visitor numbers were good but, more importantly, the quality of the leads was exceptional. It was good to be part of the EIC Pavilion and Hall 1 really does have a good buzz.

Our products of interest to visitors to Offshore Europe are packages for process (e.g. chemical injection and subsea pumps), well service (e.g. waste injection and well stimulation) and energy transition (e.g. CO2 injection and green fuel marine propulsion).

Water Jetting Association Trade Show 2025

In the second WJA trade show, we exhibited our trailer-mounted ultra-high pressure water jetting pump unit and our new 340kW pump skid. We were joined on our stands (indoor and outdoor) by TST, DERC, and Peinemann.

This exhibition was a great opportunity to meet new contacts – some from new water jetting companies and companies that are moving into the higher pressure applications in which our equipment excels.

ADIPEC 2025

Steve and Nazish will soon head to Abu Dhabi, UAE, for the ADIPEC exhibition. Find them on the EIC pavilion in hall 12.

Build Starts – Methanol Injection Pump Skid Package

The start of the build of a methanol injection pump package for offshore hazardous area operations. This pump skid will leave here designed and built to ATEX and NORSOK standards. It will have been designed in Worcester, built in Worcester, and tested in Worcester.

This is yet another pump package to feature the Hampro 70V variable stroke pump. The 70V allows a variable flow rate to be achieved without the requirement for a VSD. This technology offers significant cost savings for offshore platforms.

Read more about our:

Our Pump Skids

Our variable stroke pumps

In Design – Mobile, Road-going Well Service Pump Package

Design is almost complete on a unit that will feature an integral boiler to heat process fluids, reducing viscosity for efficient transfer. This unit will be built into an ISO container mounted on a 40-ft road-going trailer. More information.