Overview

Cleaning industrial tanks is a critical process for maintaining operational efficiency, ensuring safety, and meeting environmental and regulatory standards. Whether you’re dealing with storage tanks, process vessels, or transport containers, the cleaning method must be tailored to the tank’s contents, size, and accessibility.

This guide explains how to clean industrial tanks using high-pressure water jetting, with a focus on safe, remote, and no-man entry systems.

Step-by-Step: Cleaning Industrial Tanks with High-Pressure Water Jetting

- Assess the Tank

- Identify the type of tank (e.g., chemical, food-grade, oil storage).

- Determine the nature of residues (e.g., sludge, scale, hazardous materials).

- Determine what access flanges are available to deploy the nozzle type to be used. This will assist in determining the pump performance and appropriate method of deployment.

- Choose the Right Equipment

- Heads: Mounted inside the tank, these deliver 360° cleaning coverage.

- High-pressure pumps: Deliver water at pressures up to 3,000 bar for tough residues.

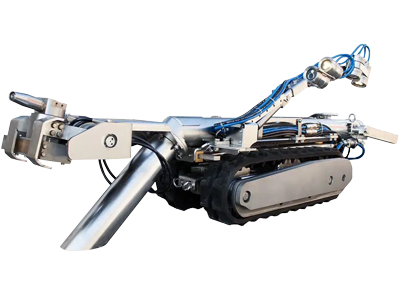

- Automated tank cleaning systems: Ideal for remote operation and confined spaces.

- 3D tank cleaning heads: Most tanks can be cleaned using a ‘3D’ tank cleaning head. These are lowered into the tank for predetermined durations and manipulated up and down within the tank until the desired cleanliness has been achieved.

- Remote Operation & No-Man Entry Systems

- Remote-controlled jetting units: Operated from outside the tank.

- No-man entry systems: Fully or semi-automated solutions that eliminate the need for personnel to enter confined spaces.

- Camera-assisted inspection tools: Allow visual monitoring during cleaning.

High-pressure water jetting is a versatile and effective method for tank cleaning. Depending on the tank and residue type, you may use:

To reduce risk and improve efficiency, most of our latest tank cleaning systems often use:

These systems are especially valuable for hazardous environments or tanks with limited access.

Safety Considerations

Tank cleaning involves significant risks, especially in confined spaces or when dealing with hazardous materials. Full and proper risk assessments must be carried out by suitably trained/qualified personnel before entering a tank or vessel.

Calder has a range of automated, semi-automated, and robotic solutions that remove the need for operators to enter the tank or vessel.

Equipment Checklist

- High-pressure pump (diesel or electric) units

- 3D tank cleaning heads

- Hose reels and lances

- Remote control unit (if applicable)

- Waterjet PPE and safety gear

- Waste collection and disposal or recycling systems

FAQs

Can I clean tanks without entering them?

Yes. Remote and automated systems allow full cleaning without manual entry, improving safety and reducing downtime.

What pressure is needed for tank cleaning?

Typical pressures range from 300 to 1,800 bar, depending on the residue and tank material.

Is chemical cleaning required?

In most cases, no. High-pressure water jetting usually removes residues without chemicals, but degreasers or neutralizers may be used when necessary.

Expert Tip

For hazardous tanks, always opt for no-man entry systems. They not only protect your team but also deliver consistent, repeatable cleaning results.

Need More Information?

If you need help selecting equipment, feel free to contact our team for advice. Call +44 1905 751790 or email sales@calder.co.uk.