Innovative Cooling Technology Designed for Offshore Electrification Projects

We are proud to announce our latest milestone in the energy transition sector: the successful design and manufacture of a cutting-edge offshore cooling pump system for a major power-from-shore project on the Norwegian continental shelf. The project supports ongoing efforts to reduce emissions from offshore operations and highlights our experience in delivering systems for hazardous environments.

Supporting the Energy Transition with Smart Engineering

As the global energy landscape shifts toward cleaner, more sustainable sources, offshore electrification has become a key strategy in reducing carbon emissions from oil and gas platforms. Our new cooling medium system, designed for ATEX Zone 1 hazardous areas, plays a crucial role in this transformation by supporting the reliable operation of electric power systems offshore.

High-Performance Cooling in Harsh Offshore Conditions

At the heart of this system is a closed-loop cooling circuit that circulates a Tri-Ethylene Glycol (TEG) and water mix at a design flow rate of over 160 cubic metres per hour. The cooling medium is pumped through Duplex stainless steel plate heat exchangers, where it is cooled using seawater before returning to the consumers.

To ensure continuous operation, the system features two centrifugal pumps – configured in duty and standby mode – driven by electric motors. This dual-pump setup allows for remote switching between pump lines, enhancing system reliability and operational flexibility in demanding offshore environments.

Built for Safety, Reliability, and Efficiency

Safety and operational integrity are paramount in offshore environments. Our system includes a skid-mounted expansion vessel with a nitrogen pre-charge, providing suction pressure to the pumps and accommodating thermal expansion of the cooling medium. Two pressure safety valves offer protection against overpressure scenarios, ensuring safe and stable operation.

The skid base is NORSOK certified, and the entire package is constructed using corrosion-resistant materials such as Duplex stainless steel and 6Mo, both of which are essential for long-term durability in seawater applications.

Smart Control and Operational Flexibility

One of the standout features of this system is its modular design, which allows the pump and motor from one line to be used in conjunction with the heat exchanger from the other. This level of operational flexibility ensures that maintenance or partial system downtime does not compromise the overall cooling performance.

The system also includes temperature and pressure control valves that continuously adjust flow based on real-time requirements, optimizing energy use and maintaining stable operating conditions.

Engineered for Harsh Environments

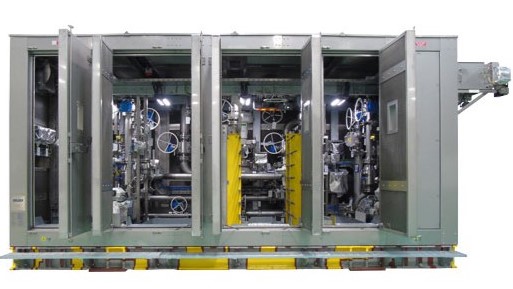

To protect the equipment and ensure operator safety, the system is housed in a robust 316 stainless steel environmental enclosure. This enclosure serves three critical functions:

1. Blast and Fire Protection – Designed to withstand explosive events and external fires, the enclosure ensures the integrity of the system under extreme conditions.

2. Noise Attenuation – Integrated soundproofing materials keep noise levels within acceptable limits, improving the working environment for offshore personnel.

3. Environmental Shielding – The enclosure protects sensitive components from salt spray, wind, and temperature fluctuations, helping maintain optimal performance.

The enclosure features both doors and removable panels for easy maintenance access and includes an HVAC unit with air filtration, mist elimination, and space heating. Check out our pump skid packages, many of which are fitted with environmental enclosures.

Precision Monitoring and Control

The expansion vessel is equipped with a visual level gauge and a level transmitter connected to the platform’s control system. Two automatic pressure control valves regulate internal pressure, while dual pressure safety valves provide redundancy for overpressure protection.

This level of instrumentation and automation ensures that the system operates within safe parameters at all times, with minimal need for manual intervention.

A Growing Portfolio in Offshore Electrification

This project adds to our growing portfolio of electric-driven pump packages, supporting the shift to cleaner offshore operations. As the industry continues to embrace cleaner energy solutions, we are proud to support our clients with reliable, efficient, and safe systems that meet the highest engineering standards.

The successful delivery of this project reflects our ability to supply complex, high-specification systems that contribute to the global energy transition. We believe that this cooling unit – and future derivatives – will be adapted for a wide range of applications, including offshore wind farms, hydrogen production, and carbon capture and storage (CCS) facilities.

Looking Ahead

As we continue to innovate and expand our presence in the energy transition sector, we remain committed to delivering solutions that are not only technically advanced but also aligned with our clients’ sustainability goals. With this project, we’ve not only delivered a high-specification cooling system — we’ve helped our client take a measurable step toward decarbonising their offshore operations.