New 340 kW (455HP) Water Jetting Unit in Build

A new model for our MultiJet range of pump units. We introduce the MultiJet 340 Pump Skid – a powerful hydro jetting unit offering increased operational efficiency.

With a robust 340 kW (455 HP) output, the MultiJet 340 is available in both diesel and electric drive configurations and can be supplied as a skid-mounted or containerised unit. The increased power translates into higher flow rates, reduced project durations, and lower operational costs – a true game changer for your water jetting operations.

Our high pressure water jetting pump units are all part of the MultiJet range.

Features

The MultiJet 340 shares the same features as our 140 and 200 models, including: boost pump, water header tank, user-friendly on-board controls, spark arrestor, and electronic throttle control (saves fuel and water).

Direct Drive

Direct drive through a flexible coupling. No Belts. No Side Loads. The integrated speed reducer in the high pressure pump gear end allows direct drive from the diesel engine, eliminating the need for large-ratio V-belts and additional guarding. This design eliminates bearing side load damage, reduces weight and maintenance requirements, and enables compact unit design.

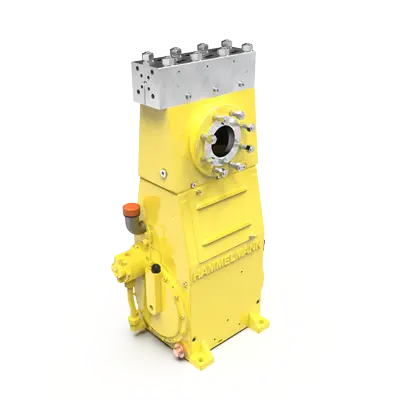

The Hammelmann Pump

Every MultiJet unit is equipped with a Hammelmann high-pressure pump – a name synonymous with reliability and performance. Calder recognised the potential of the Hammelmann pump in the UK almost thirty years ago. The superior build quality and the sealing technology make for a very efficient and reliable pump. The result? Significantly lower maintenance, increased uptime, and reduced total cost of ownership.

New MultiJet Models

- MultiJet 340 Export – Currently in build for international markets (outside the UK, USA and Europe).

- MultiJet 340 Stage 5 – Available for UK, USA and European operations.

- Multijet 470 – A 470 kW (630 HP) powerhouse for the most demanding applications.

Applications for these enhanced-power machines

- Surface Preparation: Cleaning and preparing surfaces for painting or coating.

- Concrete hydrodemolition: Cutting and demolishing concrete structures with minimal impact on surrounding areas.

- Precision Cutting: Using high-pressure water jets to cut through metals, ceramics, and other hard materials with high precision.

- Pipeline Cleaning: Removing deposits, scale, and blockages to ensure smooth flow and prevent corrosion.

- Heat Exchanger Cleaning: Clearing fouling and deposits to maintain efficient heat transfer.

- Tank Cleaning: Removing sludge, sediments, and other contaminants from storage tanks.

- Conveyor, Grid and Dolly Cleaning: For applications in food and beverage manufacturing, automotive manufacturing, pet food manufacturing, aerospace, …..

- and more …

Support

Our LifeCycle Service team are here to support you.

We have a large spares stockholding in both the UK and the Middle East. Our service team are here to support you through both planned maintenance and breakdowns, and they are never more than a phone call away.

We offer training for both safety and equipment familiarisation. For many years we have been WJA-accredited trainers and members of the WJA.

Let’s Talk

Whatever your application, we are here to help. Please call us on+44 1905 751790 or email sales@calder.co.uk to discuss how we can help.