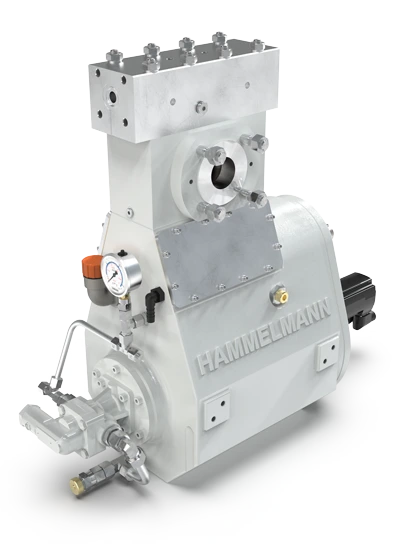

These pumps offer variable flows via adjustable stroke control. The technology of the Hampro variable stroke pump eliminates the need for a VSD, thus offering a considerable cost saving in both hardware and site installation costs.

The variable stroke pumps are the latest chapter in the progress of Hammelmann – a manufacturer of precision-engineered, high quality pumps known worldwide for their reliability. We have worked together with Hammelmann, combining their pumps and Calder packaging experience, to deliver process packages to the energy sector for over 30 years.

The variable stroke range allows precise flow rate adjustments of 0-100%. The stroke adjustment can be made automatically or manually, and while the pump is on or off load. The pump range offers flow rates of up to 203 litres per minute and pressures up to 3,500 bar. These versatile units are frequently used where the pump skid is installed in an ATEX Zone 1 hazardous area.

Hampro Variable Stroke Features:

- Variable Stroke/Variable Flow Zero to 100%.

- API 674 & API 675 Compliance.

- Zero Emissions.

- Efficiency: >95%VE & 95%ME.

- Pressures up to 3,500 bar (50,750 psi).

- MTBF: 12,000 hrs ++.

- ATEX Zone I & II Compliant.

- Material Options; 316SS, Duplex, and Super Duplex.

- Smooth, adjustment of the flow rate.

- Compact, low weight design with small footprint.

- Highly energy efficient. Flow rate adjustment without energy loss also under partial load.

Benefits of the Hampro Pump

Calder Hampro variable stroke pump packages offer signifcant benefits, particularly at higher volumes and pressures ≥200 bar:

- Significantly smaller footprint.

- Significant package weight savings.

- Energy efficient pump, converting 93% to 98% of the shaft power to hydraulic energy.

- High reliability delivering extended Mean-Time-Between-Failures (MTBF).

- Capacity to handle dirtier fluids at higher pressures.

- Reduced levels of vibration/pulsation.

- Lower noise levels.

- Zero risk of high pressure process fluid leakage to atmosphere with zero emissions option.

- Reliable control and containment of low pressure leakage.

- Eliminates the risk of contaminating hydraulic fluid.

- Pressurised power end oil lubrication & filtration system.

4 Examples of Our Experience Packaging Hammelmann Variable Stroke Pumps

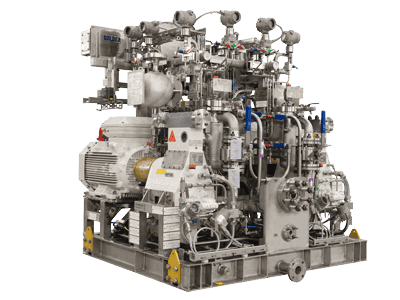

A chemical injection unit for the Johan Sverdrup field. This pump skid features twin Hampro variable stroke pumps and was designed to be compact with a minimal unit footprint.

As with all our process pump packages the unit was designed, built, and tested here at our factory in Worcester, UK.

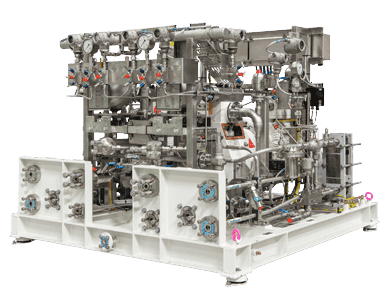

This MEG Injection Package is used for the hydrate inhibition of wells prior to start-up and shut down. The skid is designed for single point lifting and to withstand the specified external, environmental and accidental loads. The skid is supplied with a deck-mounted environmental enclosure to protect the equipment from harsh weather and to achieve the relevant platform noise level requirements.

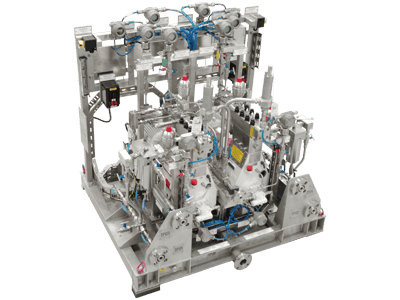

An ATEX Zone 1-compliant pump skid for TEG Injection. This pump skid package will operate on a semi-submersible platform.

The base frame was constructed using 316 stainless steel, the tubing and valves are Duplex, and the instrument tubing and fittings are manufactured in 6mo.

Three chemical injection pump packages for operation in an ATEX Zone 2 hazardous environment on an offshore platform.

Comprising two LDHI AA (low density hydrate inhibitor) units, and one methanol unit, they are part of a larger scope of supply for a gas and condensate field located in the Caspian Sea.

The customer and the end user witnessed the full F.A.T. using our – remote test viewing facility. The pump units were then prepared for long-term preservation prior to despatch.

Where to see Hammelmann Hampro Variable Stroke Pumps

We will once again be at this year’s Offshore Europe exhibition in Aberdeen – 2-5 Septmber 2025. On our stand will be a working demonstration unit that features the Hampro 20V pump. If you can’t wait until September, then please get in touch with us. We shall also be exhibiting at ADIPEC 2025 from 3-6 November in Abu Dhabi.

Talk with Us

Whatever your application, we are here to help. Please call us on +44 1905 751790 or email sales@calder.co.uk to discuss how we can help you with your next process project.

More Information on our Process Pump Units

Boosting, Circulation and Cooling Pumps

Chemical Injection Packages

CO2 Injection Pumps

Geothermal Energy Recovery Pump Systems

MEG, TEG, and Methanol Injection Pumps

Power-to-X Pump Systems (P2X)

Produced Water Injection Pumps